References

From: Jason Mank

To: Erwin Schwartz

Date: Thu, 1 Mar 2018 15:48:13 +0000

Subject: DDI Heat exchangers reference letter

To whom it may concern,

The 2 Rectangular channeled Sludge Heat Exchangers that DDI Heat Exchangers Inc. sold and were installed in the city of Waterloo from the beginning of 2014 are working as designed, and did not get plugged in all this years of operation. When we opened for inspection after three years, the unit looked like new, with no pitting or signs or wear. The only thing that needed replacement was the consumable gasket on the inspection hatch.

Also, the support we received from DDI Heat Exchangers and training was professional, they came back after the unit had been operating for two years and gave all staff a refresher course in operation and maintenance.

We are happy with the DDI Heat Exchangers performance and the support we got.

Regards,

Jason Mank

Operations & Maintenance Team Lead | Ontario Clean Water Agency

15 Oct 2014

From: Higgins, Richard

Sent: Tuesday, October 14, 2014 2:20 PM

To: John Glasgow

Cc: Erwin Schwartz

Subject: FW: DDI Hex

John,

A couple of questions to follow up:

Please let me know any other comments about condition of HEX after 5 years of service? It looks like it has performed well and provided very good service? Excellent condition and good service.

Just curious what was reason for inspection? Operators typically open to clean only if required. Did you notice higher than normal pressure drop? There has been no problems, we have had the DDI for 6 years and decided due diligence demanded we clean and inspect the inside.

John Glasgow

Maintenance Supervisor II

Lions Gate Wastewater Treatment Plant

Maintenance WWTP Division

Operations & Maintenance Division

Metro Vancouver

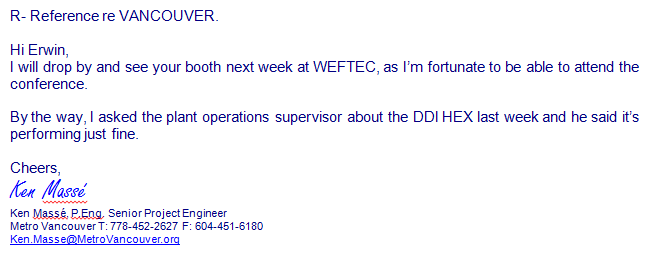

==================================

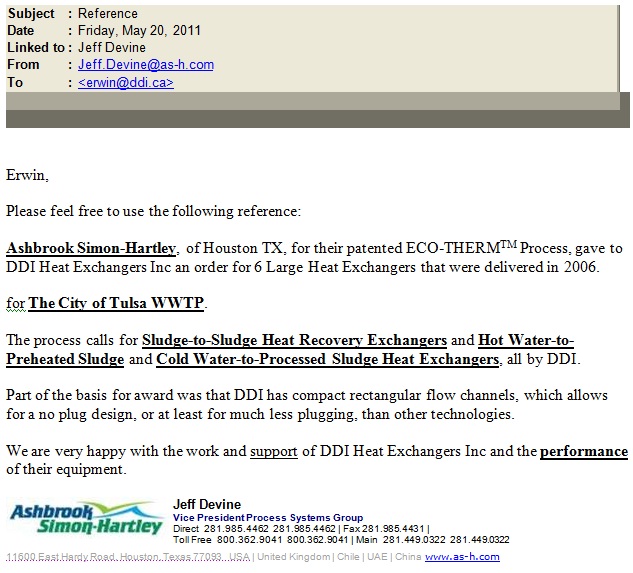

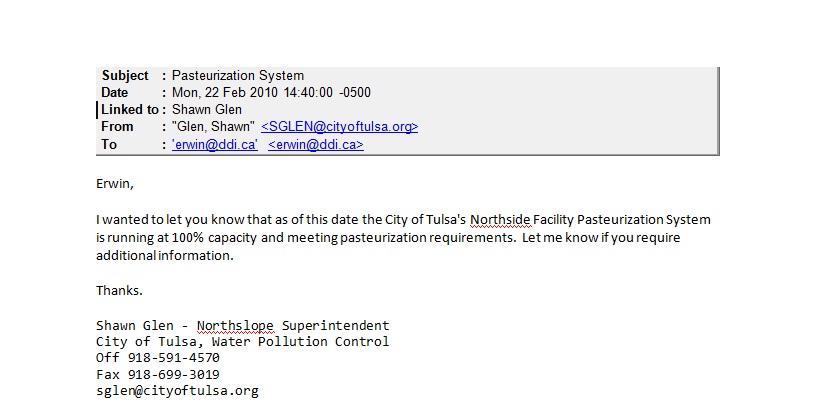

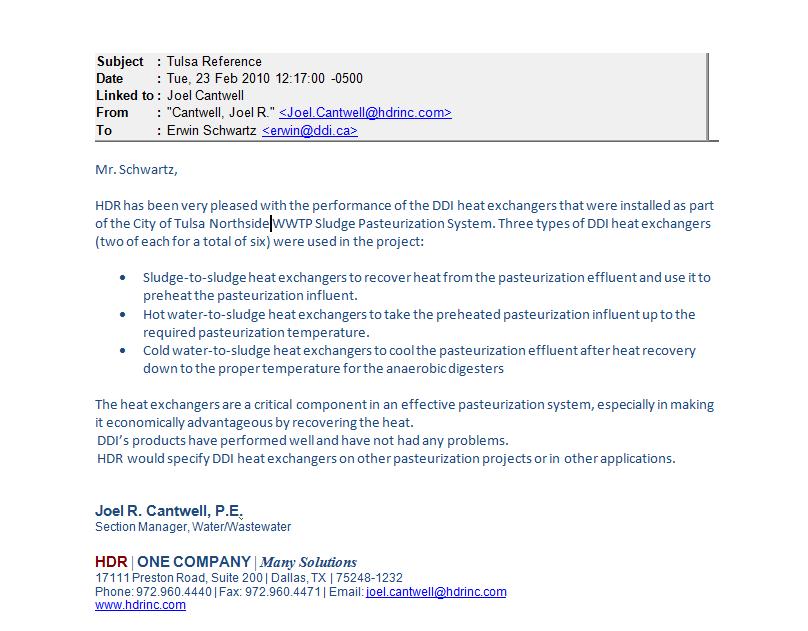

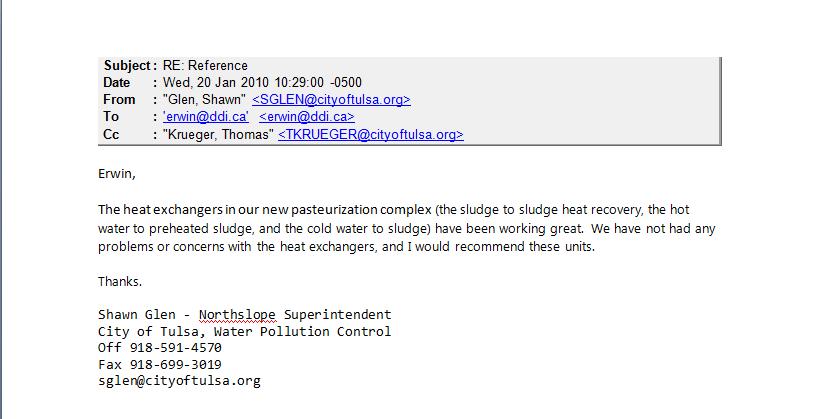

From: “Martin, Kip” <KMartin@cityoftulsa.org>

To: “Erwin Schwartz (erwin@ddi.ca)” <erwin@ddi.ca>

Date: Tue, 15 Jul 2014 10:16:13 -0500

Subject: Pasteurization system

We have had many problems with the pasteurization system since it was started up in 2007. We had to change pumps, grinders, controls, valves, piping, etc. The only components we didn’t have problems with were the heat exchangers. When we modified the system to eliminate the vessels and no longer attempted to pasteurize the sludge we employed one pump, one heat exchanger, and the boiler leaving the other equipment idle. We heat the sludge and send it to the digesters where the treatment takes place for class B biosolids.

Kip Martin | Operations Supervisor

City of Tulsa Water & Sewer Department

5628 N. 105 E. Ave. Tulsa, OK 74117

T: 918-591-4552

F: 918-699-3946

E: kmartin@cityoftulsa.org

www.cityoftulsa.org

01 April 2011

With the financial support of the Emerging Technologies Program at Natural Resources Canada, DDI successfully designed and built a Rectangular, Square, Cube TM heat exchanger for heat recovery from a liquid with a high solids content. The heat exchanger was installed for a test at a factory in the USA. The Rectangular, Square, Cube TM unit was used to recover heat from a stream of hot molasses containing approximately 65% solids. During the test the heat exchanger operated at its designed effectiveness and did not plug.”

Tom Jewett, P.Eng.

Industrial Applications Officer

CanmetENERGY

Government of Canada/ Natural Resources Canada

Building 3, Room 204 Édifice 3, bureau 204

1 Haanel Drive, Nepean, Ontario K1A 1M1

Telephone (613) 996-0890 , Facsimile: (613) 995-7868

TECHNICAL MEMORANDUM CH2MHILL

Heat Exchanger Vendor Reviews for Approved Equipment List

PREPARED FOR: Josh Shurr-Region of Halton

PREPARED BY: Brandon Elliott

Jose Bicudo

Don Holland

DATE: June 20, 2005

PROJECT NUMBER: 324762

Objective

The objective of this Technical memorandum is to report the results of the heat exchanger

vendor reviews for the Region of Halton’s approved equipment list.

Summary

The heat exchangers were evaluated based on the equipment review criteria developed by

the Region, but modified to better suit the type of equipment being reviewed. The

definitions of the terms (used as criteria) are given in the vendor review tables in Appendix

A. The scores were scaled to a final score out of 100, and a score of less than 50% was

considered to be a fail. The following heat exchanger manufacturers/suppliers were

contacted: Napier-Reid, Walker, and DDI. The three manufacturers/suppliers evaluated,

passed the review with the following scores: l) Napier-Reid – 83.3%, 2) Walker – 60.4%, 3)

DDI – 90.4%. DDI Heat Exchangers obtained an overall higher score than the other two

manufacturersbecause they only have two installations in operation, which indicates

limited practical experience. The two references provided by DDI described the heat

exchangers to be reliable and problem free, and as a result, they scored high on quality and

maintainability. DDI also had the lowest cost of the compared heat exchangers, and scored

high in that category. DDI was not severely penalized for a lack of references, because

references only had a weighting of l. The following are recommended for the approved

equipment list.

1) Napier-Reid

2) Walker

3) DDI Heat Exchangers

All of the manufacturers/suppliers passed the review and were found to be acceptable for

the approved equipment list for the Region of Halton.

5 Feb 2009

Erwin, your name is gonna stick in my mind…for several reasons: You don’t quit until you’ve explored all options and possibilities.

You obviously want to have satisfied customers, not just make a sale…..a person wishing only to make a sale will give it all in a couple of “blows” then, buy it or not, they’re done.

You also obviously know your business and this day and time that’s not terribly easy to find.

I thank you very much for the effort you’ve gone to for me on this. It will not be forgotten.

A question for you: Do you ever come to the US and are you coming toward East Tennessee anytime soon? If you were to be, i’d very much like to set up a meeting with you and our Engineering group for you to discuss heat exchangers.

Take care and again, MANY THANKS for your help.

Lynn Herron

Engineering Projects

(423) 534-0428

![]()

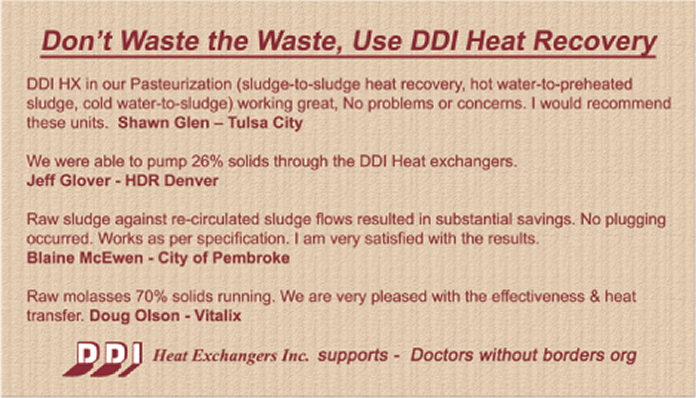

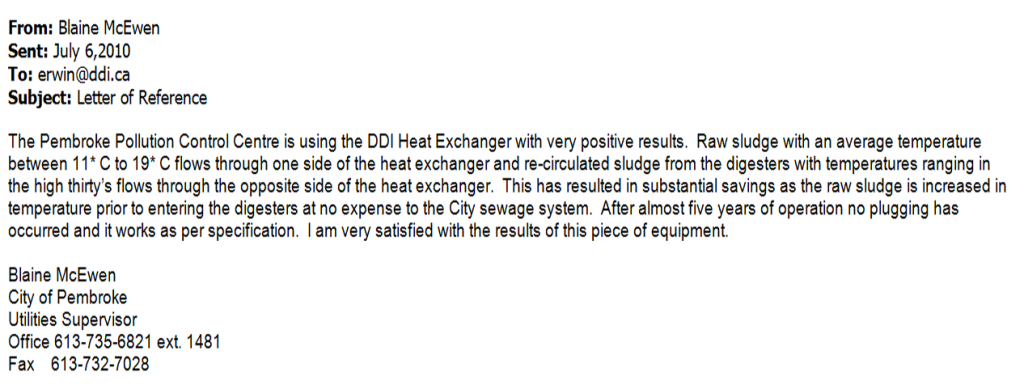

The Pembroke Pollution Control Centre is using the DDI Heat Exchanger with very positive results. Raw sludge with an average temperature between 11* C to 19* C flows through one side of the heat exchanger and re-circulated sludge from the digesters with temperatures ranging in the high thirty’s flows through the opposite side of the heat exchanger. This has resulted in substantial savings has the raw sludge is increased in temperature prior to entering the digesters at no expense to the City sewage system. After almost two years of operation no plugging has occurred and it works as per specification. I am very satisfied with the results of this piece of equipment.

David Atkinson

City of Pembroke

Utilities Superintendent

Office 613-735-6821 ext. 1490

Cell 613-281-2141

Fax 613-732-7028

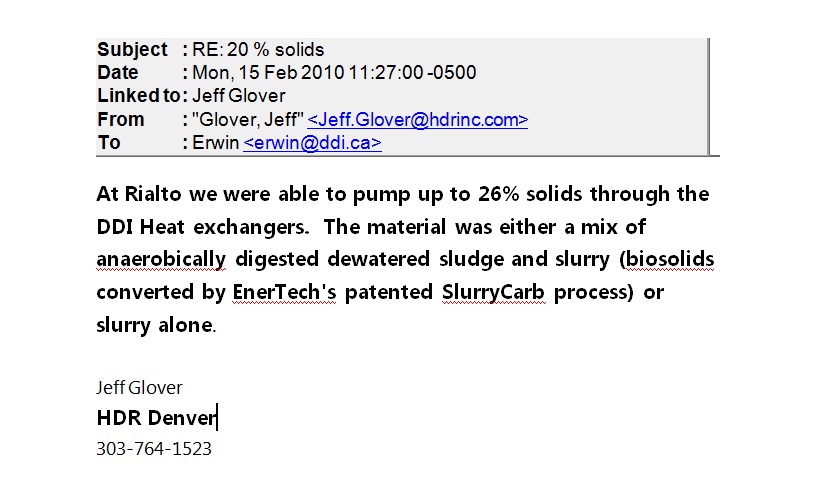

12 Sep 2007

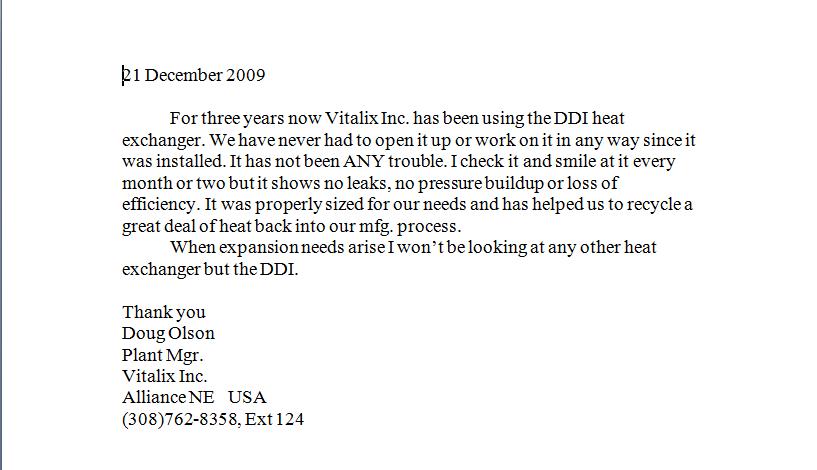

Vitalix Inc. has been using the DDI heat exchanger almost a year now with very positive results. Raw molasses at 65% to 70% solids is running on one side and hot water on the other. We have had no problems with plugging or pressure buildup. We are also very pleased with the effectiveness of this unit in heat transfer. Thank you for your help and support.

Plant Mgr. Doug Olson

308-762-8358

Vitalix Inc.

Alliance NE.

Views Today : 438

Views Today : 438 Total views : 453421

Total views : 453421